THE FUNCTIONALITY OF THE AN PUMP.

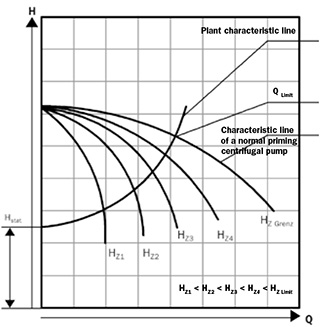

The manner in which V-AN pumps work can be described using a family of curves. The upper limit for these is the characteristic curve for a normal pump. The delivery height and feed volume flow determine the height of the liquid in the pump reservoir. The working point always lies on the characteristic curve of the plant between zero flow and Qlimit (Qlimit is given by the intersection of the characteristic curve of the plant with the characteristic of the "normal-priming" type of centrifugal pump). HZ limit varies between 0.5 and 2.0m – depending on the pump size and speed. At HZ limit, the V-AN behaves like a normal-priming pump. Their NPSH value is zero. As a result it operates cavitation-free, provided that the pressure in the pump reservoir does not fall below the vapour pressure.

Any gas bubbles that get into the pump are also pumped through. Some are also returned to the pump reservoir via a gas compensation line, however. If nothing flows into the suction container, the pump maintains the static height of the plant at zero delivery. Its technical features allow the V-AN to be operated for as long as required at Q = 0 m³/h. However, the temperature increase of the pumping medium must not impair the corrosion behaviour of the material.

Impeller back vanes completely, i.e. hydrodynamically, depressurise the secondary seal of the pump (e.g. packed gland or double mechanical seal). For this reason, medium can never escape into the environment via the shaft seal, including in the variant with the packed gland. To ensure this the pump must be started and stopped correctly, however. The V-AN can furthermore be filled and cleaned with flushing water through the inlet port before it is switched off.